|

|

|

|

|

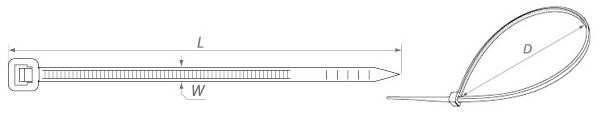

Clamps for cable polyamide 12

Cable clamps are made of thermoplastic polyamide 12 and are designed for binding cable bundles of various sections (for cable ties). They have a lock-clasp.

They are used when tying cables and wires for subsequent laying in corrugated or rigid smooth pipes, cable channels and ducts or on trays. Clamps made of polyamide 12 are highly resistant to oils and their derivatives.

Installation temperature : from 0 ° C to + 60 ° C

Operating temperature: from -40 ° C to + 85 ° C

They have increased dielectric strength.

They are available in various lengths and widths (depending on the cable bundle). Meet the requirements of safety standards.

|

|

|

|

| Code |

Maximum

working

load, kg |

Width (W), mm |

Length (L), mm |

D * |

Quantity, pcs.

packaged |

| 45820 |

55 |

7.6 |

200 |

3-50 |

100 |

| 45830 |

55 |

7.6 |

300 |

4-82 |

100 |

| 45835 |

55 |

7.6 |

350 |

4-90 |

100 |

| 45840 |

55 |

7.6 |

400 |

4-105 |

100 |

| 45845 |

55 |

7.6 |

450 |

4-118 |

100 |

| 45850 |

55 |

7.6 |

500 |

4-150 |

100 |

| 45865 |

55 |

7.6 |

650 |

8-190 |

100 |

|

|

| * D - diameter of the bunch of cables (minimum / maximum) |

|

|

|

|

|

|

|

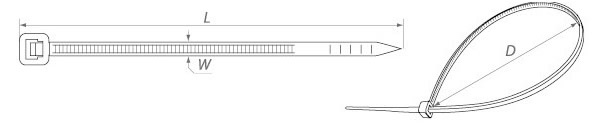

Nylon / polyamide cable clamps

Cable clamps are made of nylon / polyamide (thermoplastic material) and are intended for binding (tie) cable bundles of various sections. They have a lock-clasp.

They are used when tying cables and wires for subsequent laying in corrugated or rigid smooth pipes, cable channels and ducts or on trays. They are highly resistant to oils and their derivatives.

Installation temperature : from 0 ° C to + 60 ° C

Operating temperature: from -40 ° C to + 85 ° C

They have different lengths and widths (depending on the cable bundle) and are an integral part of any electrical wiring.

|

|

|

|

| Code |

Maximum

working

load, kg |

Width

(W), mm |

Length

(L), mm |

D * |

Qty in a

package |

| 45080 |

eight |

2.5 |

80 |

2-16 |

100 |

| 45100 |

eight |

2.5 |

100 |

2-22 |

100 |

| 45150 |

eight |

2.5 |

150 |

2-35 |

100 |

| 45160 |

eight |

2.5 |

160 |

2-40 |

100 |

| 45200 |

eight |

2.5 |

200 |

3-50 |

100 |

| 45151 |

eighteen |

3.5 |

150 |

3-35 |

100 |

| 45201 |

eighteen |

3.5 |

200 |

3-50 |

100 |

| 45250 |

eighteen |

3.5 |

250 |

3-65 |

100 |

| 45300 |

eighteen |

3.5 |

300 |

3-80 |

100 |

| 45202 |

22 |

4.8 |

200 |

3-50 |

100 |

| 45252 |

22 |

4.8 |

250 |

3-65 |

100 |

| 45282 |

22 |

4.8 |

280 |

3-70 |

100 |

| 45302 |

22 |

4.8 |

300 |

3-82 |

100 |

| 45350 |

22 |

4.8 |

350 |

3-90 |

100 |

| 45400 |

22 |

4.8 |

400 |

3-105 |

100 |

| 45430 |

22 |

4.8 |

430 |

3-110 |

100 |

| 45451 |

22 |

4.8 |

450 |

3-130 |

100 |

| 45501 |

22 |

4.8 |

500 |

3-150 |

100 |

| 45183 |

55 |

7.6 |

180 |

3-42 |

100 |

| 45203 |

55 |

7.6 |

200 |

3-50 |

100 |

| 45253 |

55 |

7.6 |

250 |

4-63 |

100 |

| 45303 |

55 |

7.6 |

300 |

4-82 |

100 |

| 45355 |

55 |

7.6 |

350 |

4-90 |

100 |

| 45405 |

55 |

7.6 |

400 |

4-105 |

100 |

| 45540 |

80 |

7.6 |

540 |

4-150 |

100 |

| 45550 |

80 |

9.0 |

550 |

8-160 |

100 |

| 45650 |

80 |

9.0 |

650 |

8-190 |

100 |

| 45750 |

80 |

9.0 |

750 |

10-225 |

100 |

| 45900 |

80 |

9.0 |

900 |

10-295 |

100 |

| 45999 |

80 |

9.0 |

1020 |

10-295 |

100 |

| 45701 |

91 |

10.0 |

700 |

10-125 |

100 |

|

|

| * D - diameter of the bunch of cables (minimum / maximum) |

|

|

|

|

|

|

|

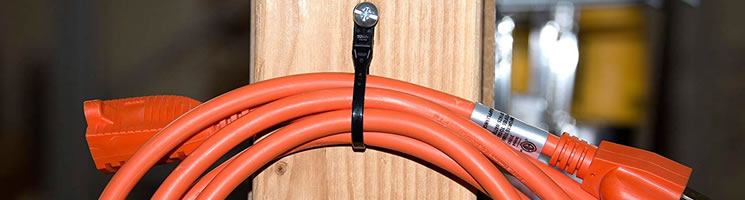

Cable clamps (black)

Cable clamps are made of nylon / polyamide (thermoplastic material) and are intended for binding (tie) cable bundles of various sections. They have a lock-clasp.

They are used when tying cables and wires for subsequent laying in corrugated or rigid smooth pipes, cable channels and ducts or on trays. They are highly resistant to oils and their derivatives.

Installation temperature : from 0 ° C to + 60 ° C

Operating temperature: from -40 ° C to + 85 ° C

They have different lengths and widths (depending on the cable bundle) and are an integral part of any electrical wiring.

|

|

|

|

| Code |

Maximum

working load, kg |

Width (W), mm |

Length (L), mm |

D * |

Quantity, pcs.

packaged |

| 45100 BL |

eight |

2.5 |

100 |

2-22 |

100 |

| 45150 BL |

eight |

2.5 |

150 |

2-35 |

100 |

| 45200 BL |

eight |

2.5 |

200 |

3-50 |

100 |

| 45201 BL |

eighteen |

3.5 |

200 |

3-50 |

100 |

| 45250 BL |

eighteen |

3.5 |

250 |

3-65 |

100 |

| 45300 BL |

eighteen |

3.5 |

300 |

3-80 |

100 |

| 45302 BL |

22 |

4.8 |

300 |

3-82 |

100 |

| 45350 BL |

22 |

4.8 |

350 |

3-90 |

100 |

| 45400 BL |

22 |

4.8 |

400 |

3-105 |

100 |

| 45403 BL |

55 |

7.9 |

400 |

|

100 |

| 45455 BL |

55 |

7.6 |

450 |

4-118 |

100 |

|

|

| * D - diameter of the bunch of cables (minimum / maximum) |

|

|

|

|

|

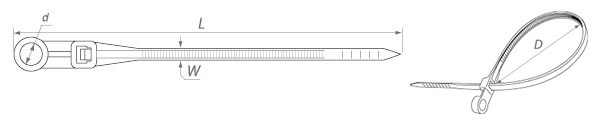

Cable clamps with mounting hole

Cable clamps are made of nylon / polyamide (thermoplastic material) and are intended for binding cable bundles of various cross-sections (for cable ties). They have a lock-clasp.

They are used both for bundling cables and for direct fastening of cables, wires, as well as flexible and rigid pipes to the bearing surface. They are highly resistant to oils and their derivatives.

Operating temperature of installation and operation: -40 ° C to + 80 ° C.

They are available in various lengths and widths (depending on the application) and are an integral part of any electrical wiring.

|

|

|

|

| Code |

Maximum

working

load, kg |

Width (W), mm |

Length (L), mm |

Diameter (D) mm |

Quantity, pcs.

packaged |

| 45109 |

eighteen |

3.5 |

110 |

22 |

100 |

| 45159 |

eighteen |

3.6 |

150 |

32 |

100 |

| 45209 |

eighteen |

4.3 |

220 |

42 |

100 |

| 45109BL |

eighteen |

3.5 |

110 |

22 |

100 |

| 45159BL |

eighteen |

3.6 |

150 |

32 |

100 |

| 45209BL |

19 |

4.3 |

220 |

42 |

100 |

|

|

|

|

|

|

|

|

|

|

|

Determination of

Minimum Tensile Strength The minimum tensile strength of a cable tie is a critical selection criterion for a cable tie. It expresses the load on the screed - i.e. how much cable ties can carry the load.

Test procedure for determining minimum tensile tensile strength:

|

|

|

|

|

A - screed mounted on the sliding tubular mandrel and tightened circumferentially

B - A sliding mandrel is expanded vertically with a certain fixed rate

in - Locked load at which the tie is broken. This value is indicated in N (Newtons) and is written into the test program on the built-in computer. Likewise, the recalculation of the load mass (kg) is recorded and the test graph is displayed.

Method for calculating the minimum values of tensile strength

What does the minimum breaking stress with a force of 225N (Newton) mean for Russia, the CIS and the EU, or is it 50 (LBS) pounds for the USA and England?

To explain what this value means, the mass is calculated as follows. By definition, mass is expressed in kg. Accordingly, the load is calculated as follows: H = (kg * m / s 2 )

Then the formula for calculating the mass is as follows:

Mass (kg) = minimum force stress / gravitational acceleration M = N / g Gravity acceleration = 9.81 m / s 2 Therefore: Mass = minimum force stress / (kg * m / s 2 ) / 9.81 (m / s 2 )

For example, with a minimum force of 225N (= 50LBS / lb) mass = Mass = 225 (kg * m / s 2 ) / 9.81 (m / s 2 ) or Mass = 225 / 9.91 kg = 22.9 kg Thus, a screed with parameters (ARTICLE EKOPLAST) with a width of 4.8 mm corresponds to a minimum breaking force of 225N and can be loaded by 22.9 kg, in fact this load is passed by a series of ties (cable clamps) EKOPLAST 3.5 mm wide (see ARTICLES EKOPLAST), respectively, we can perform the reverse payment. The calculation with the required load for the minimum breaking force is calculated through the mass: Minimum breaking force = Mass * 9.81 (m / s 2 ) If the tie is loaded, for example, with a mass = 11 kg, then the minimum breaking force = 11 kg * 9.81 (m / s 2

) = 108 N, which corresponds to a series of ties (cable clamps) EKOPLAST with a width of 2.5 mm.

Thus, with a load of 11 kg, the tie (cable clamp) must have a minimum breaking force of 108 N.

And with a load of 53 kg, the minimum breaking force will be 520N according to the above formula. This value corresponds to a series of EKOPLAST screeds with a width of 7.6 mm

|

|

|